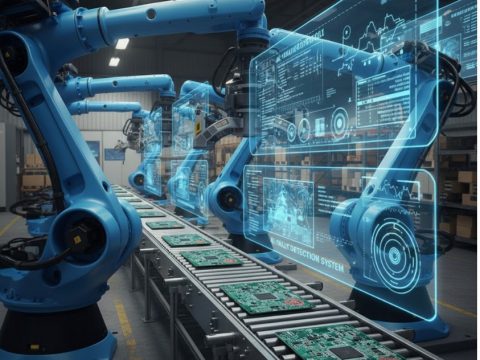

How Refurbished Robotics Is Accelerating Battery and Electric Vehicle Component Manufacturing

The rapid rise of electric mobility is transforming global manufacturing. Battery gigafactories demand high‑precision automation, controlled environments, and scalable production capacity. Yet many companies encounter a major challenge: high investment costs for industrial robots. Refurbished robotics is eliminating this barrier—driving growth, sustainability, and accessibility in the EV sector. Key Advantages of Refurbished Industrial Robots Cost